- Joined

- Jul 23, 2011

- Messages

- 3,825

- Reaction score

- 1,013

- Location

- Rhondda Cynon Taff

- Hive Type

- National

- Number of Hives

- 30

It's an infinity pool.Have you tried turning it over?

James

It's an infinity pool.Have you tried turning it over?

James

The thin rebates are on the bottom of the roof, I've done that with some and the main top has the rebates facing the galvanised sheet.No.

Think upside down.

tht's the other option I thought - still the same though, the grooves are probably the same use at the bottom than at the top totally superfluous for any purpose. In fact I think I did one like that for someone at my association years ago - he didn't notice, neither did the bees.No.

Think upside down.

tht's the other option I thought - still the same though, the grooves are probably the same use at the bottom than at the top totally superfluous for any purpose. In fact I think I did one like that for someone at my association years ago - he didn't notice, neither did the bees.

Which is good, the bees just draw it out and build cells with it ,saving them the work and effort of producing more wax, if you buy good quality Eastern European wax foundation it's a lot thicker than the offerings we get over here - and it's seen as a mark of quality.It's still thicker than bought foundation,

Which is good, the bees just draw it out and build cells with it ,saving them the work and effort of producing more wax, if you buy good quality Eastern European wax foundation it's a lot thicker than the offerings we get over here - and it's seen as a mark of quality.

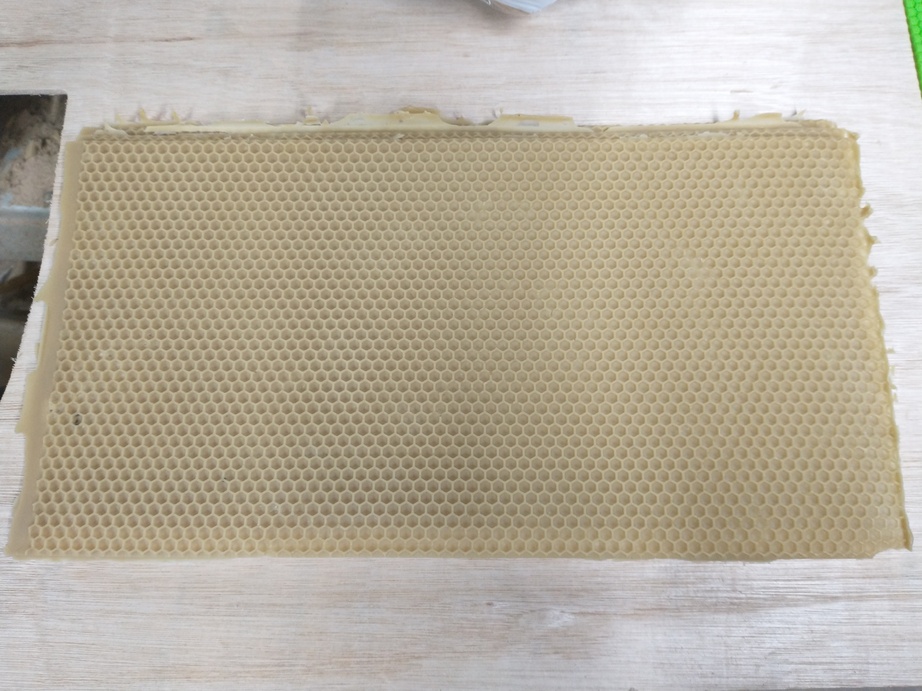

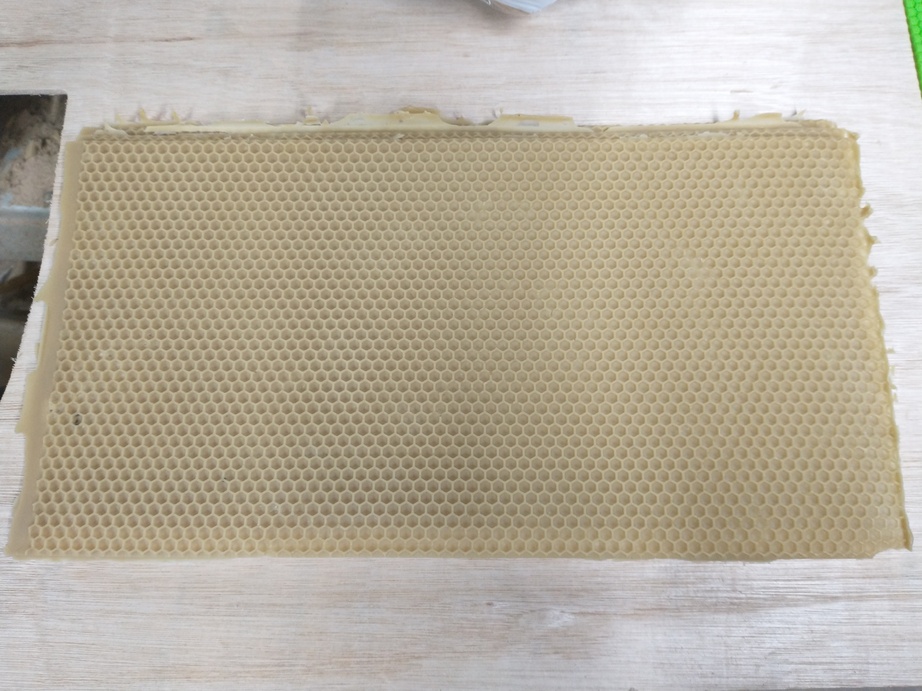

Is that moulded or pressed? Looks goodFlushed with my success at getting the car door open, I decided to wait before removing the lock and replacing it as there's fiddly stuff to be done and only a couple of hours of daylight left, so I moved on to my next experiment with wax: making my own foundation.

It took me a few goes (but only a few) to get the hang of things. I'm not sure it's an ideal job to attempt when the air temperature is only a few degrees above freezing, but by the third one I felt that I was getting the idea.

It's still thicker than bought foundation, and brittle too, I reckon it will make nice starter strips though. Just need to trim it to size.

James

Is that moulded or pressed? Looks good

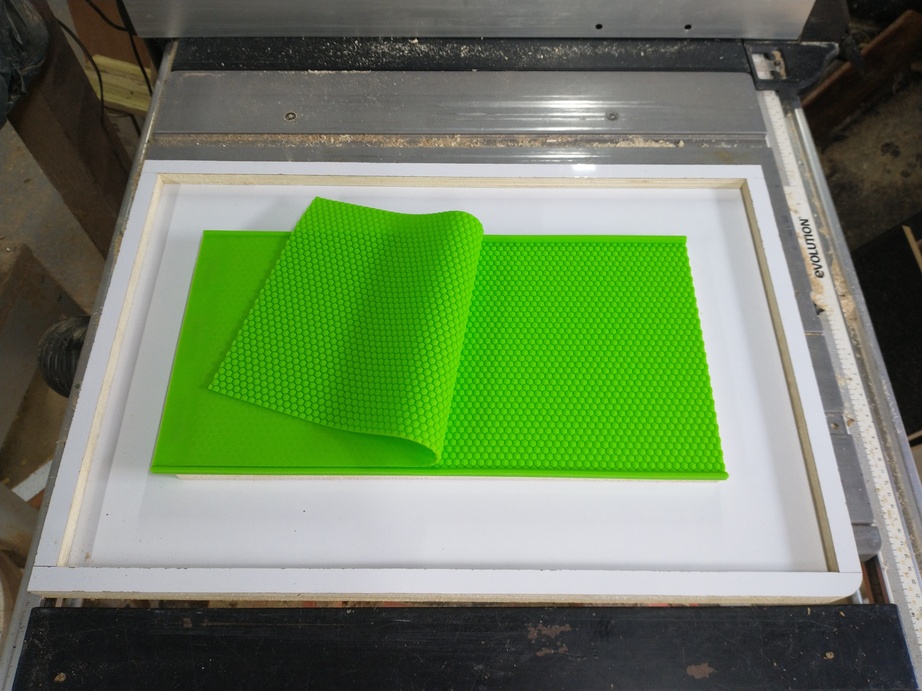

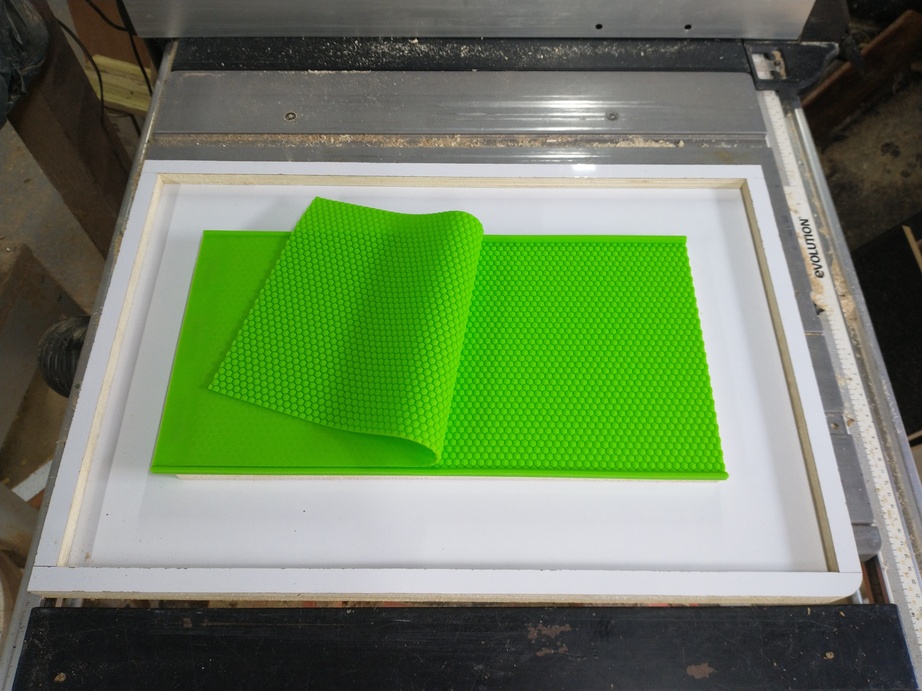

Do the two sheets align properly so that the bases of the cells meet like natural comb?I guess I'd describe it as moulded. It's not an embossed pattern pressed into a flat sheet of wax, at least. Whilst I can see the appeal of the latter method (especially if the wax is then more flexible), I can't justify the cost of the machinery to do it.

I have a pair of embossed silicone sheets bought from Amazon:

After pouring molten wax onto the lower sheet I rolled the top one across it and then ran a wooden block across the top to spread the wax and expel any excess which I scraped up and returned to the melter whilst the sheet was setting.

I did consider trying to fix the top sheet to a hinged "lid" that folds down onto the molten wax. I might still attempt that. We'll see how it goes.

James

They align well enough. Don't underestimate the bees ability to sort out any slight misalignment.Do the two sheets align properly so that the bases of the cells meet like natural comb?

Do the two sheets align properly so that the bases of the cells meet like natural comb?

Thanks, I was wondering whether it was easy to get them aligned.Just been out to check. The alignment isn't absolutely perfect, but it really isn't very far off. Quite possibly more down to me getting the sheets misaligned rather than the mould being wrong.

James