Anyone know of a food grade paint for extraction equipment? One for metal and one for wood? Or preferably one for both?

Thanks,

Andrew

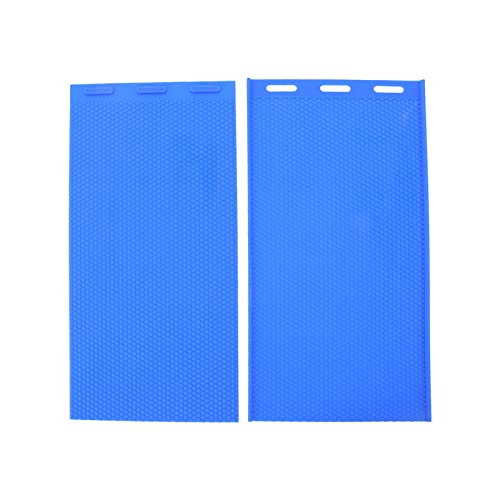

This is what i used on my extractor.

USDA APPROVAL: Yes Made by parker coatings in Green Bay, Wisconsin

CHEMSEAL 1600-APU Technical Data

ALIPHATIC POLYESTER URETHANE

DESCRIPTION: Chemseal 1600-APU is a two-component aliphatic polyester urethane enamel designed for

exterior/interior surfaces. Its tough durable finish is unsurpassed for its ability to withstand impact and

abrasion. Flexibility, superior hardness, adhesion and fast dry makes it an ideal product for many industrial

applications.

RECOMMENDED USES: Warehouses - storage areas - industrial and manufacturing plant floors - aisleways

- machinery and equipment - vehicles - exterior metal - auto service areas.

CHEMICAL RESISTANCE: Skydrol, MEK, hydraulic and brake fluid, gasoline and many other solvents

and chemicals. For additional chemical resistance please consult the Parker Technical Department for your

specific requirements.

PHYSICAL CHARACTERISTICS: Excellent flexibility and light stability. Good penetration for secure

bond.

FINISH: Gloss

VOLUME SOLIDS: 50% +- 1% depending on color

FLASH POINT: Part A: 76 degrees. F. Seta Flash

Part B: 76 degrees. F. Seta Flash

SUGGESTED DRY FILM THICKNESS: 2-4 mils per coat

EXPECTED COVERAGE: 600-300 square feet. per unit at suggested DFT

COLORS: Various

PACKAGING: 1 unit = 1/2 gallon Part A, Activator

1 gallon Part B, Base

SHIPPING WEIGHT: 1 unit = 15 lbs.

USDA APPROVAL: Yes

All technical advice, recommendations and services are rendered by the Seller gratis. They are based on technical data which the

Seller believes to be reliable, and are intended for use by persons having skill and know-how, at their own discretion and risk. Seller

assumes no responsibility for results obtained or damages incurred from their use by Buyer in whole or in part. Such

recommendations, technical advice or services are not to be taken as a license to operate under or intended to suggest infringement of

any existing patent.

PARKER COATINGS, INC. - 2451 W. MASON ST. - GREEN BAY, WI 54303

800-236-9676 920-494-9676

CHEMSEAL 1600-APU Application Data

ALIPHATIC POLYESTER URETHANE

SURFACE PREPARATION: General Surface Preparation Instructions: NEW CONCRETE - Remove all

dust, dirt, grease and other foreign materials. For maximum adhesion acid etching is required. Surface must be

thoroughly dry before application. METAL should be cleaned by solvent degreasing. WOOD should be free of

dust, dirt, grease and other foreign materials. On TILE remove all wax or topcoat and clean thoroughly.

PRIMER: Probond 26-CP. Contact Parker Coatings’ Technical Dept. for specific requirements.

MIXING: Mix Part A into Part B for 3-5 minutes. Allow approximately 5-10 minutes for induction time

before application.

POT LIFE: 45 minutes - 1 hour at 70 degrees. F. and 50% R.H.

APPLICATION TEMPERATURE: Do not apply when temperature is below 50 degrees. F. Temperature of

substrate should be 50-70 degrees. F.

CURE TIME: Tack free - 1 hour. Recoat - 6-16 hours at 70 degrees. F. and 50% R.H.

APPLICATION: Apply by brush, roll or spray. If roll application is used, use a 3/8” nap roller cover. Do

not over roll or product gassing may occur. When spraying, consult the “Safety and Handling of Poly-

Isocyanate Bulletin”. Do not apply when excessive moisture is present.

CLEAN UP: Clean spills and tools immediately with P30T Thinner

CAUTION: It is recommended that the personnel observe good personal hygiene. Certain personnel may be sensitive to various

types of resins which may cause dermatitis. Do not use in confined space or closed area without adequate ventilation. This product

may be irritating to eyes and skin. Avoid contact with liquid components A and B and keep mortar from touching tool handles and

clothes. Use coveralls, goggles, rubber gloves or protective cream. Always wash thoroughly with soap and warm water after use.

Should accidental eye contact occur, wash thoroughly with water and consult a physician immediately. U.S. Department of Labor

approved material data sheet is available.

LIMITED WARRANTY: The Manufacturer warrants this product to be free from defects in material and workmanship under

normal use and service for a period of one year of the date of purchase. The Manufacturer’s sole liability shall be limited to replacing

this product if, within one year of the date of purchase, it is shown to be defective. THIS WARRANTY IS EXPRESSLY IN LIEU OF

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE WARRANTIES OF MERCHANTABILITY AND

FITNESS OF PURPOSE. THE MANUFACTURER SHALL NOT BE LIABLE FOR INDIRECT, INCIDENTAL,

CONSEQUENTIAL OR OTHER DAMAGES OF ANY KIND. This warranty shall not be extended, altered or varied except by a

written instrument signed by the Manufacturer.

6/96