The Apprentices

House Bee

- Joined

- Jun 20, 2011

- Messages

- 462

- Reaction score

- 1

- Location

- North Yorkshire.

- Hive Type

- warre

- Number of Hives

- 3 Modified Warre

i bet the apprentices could turn their hand to making frames with drawn wooden foundation judging by quality of the wood working/joinery.

Heh

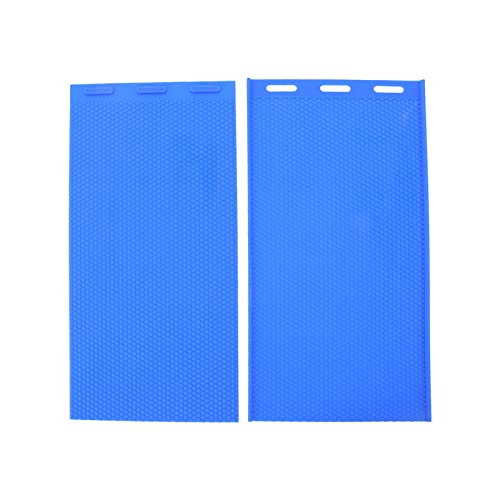

I'm gonna have a go at making a foundation mould from instruction on an African beekeepers blog.

They made theirs using silicone rubber and a frame around it.

The pour the liquid mix over an existing sheet so get the patterns in the mold.

The guys there say they can make 50 sheets an hour.

Search for, Bush Mechanic-beeswax foundation mold.

I am also trying out another idea of mine for making starter strip/ possibly full length, its a warm pour cold water dip tank process similar to the bush mechanic costing very little to make, only time which costs me little these days.

If things work well I will share the findings.